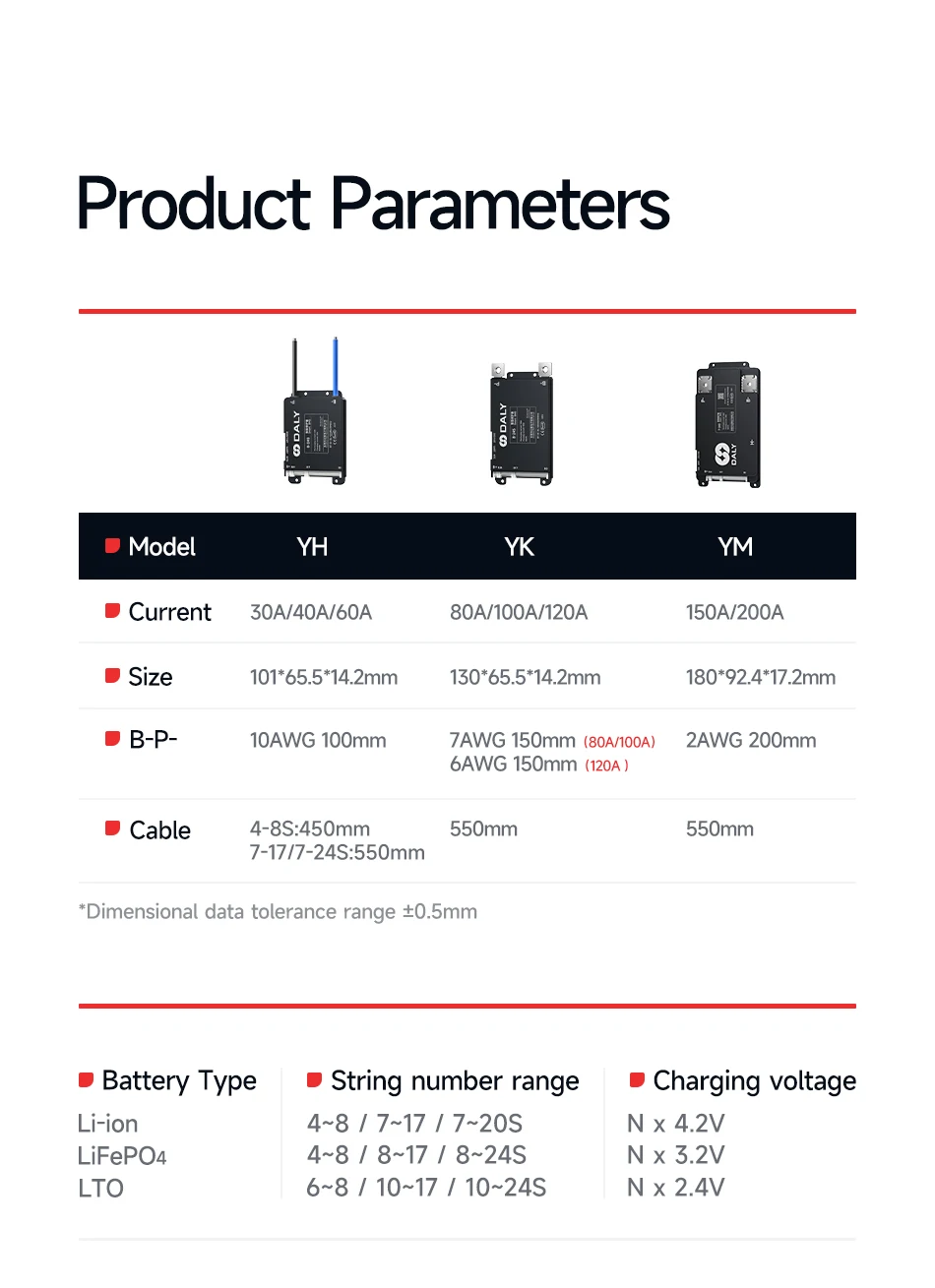

DALY Smart BMS 4S 5S 6S 7S 8S 17S 20S 24S 12V 24V 48V Lifepo4 BMS 30A 40A 60A 80A 100A 120A Li-Ion LTO 3.7V 3.2V Battery BMS

|

Model |

|||||||||||

|

DALY SMART BMS: Y-series 30-60A(YH) 80-120A(YK) |

|||||||||||

|

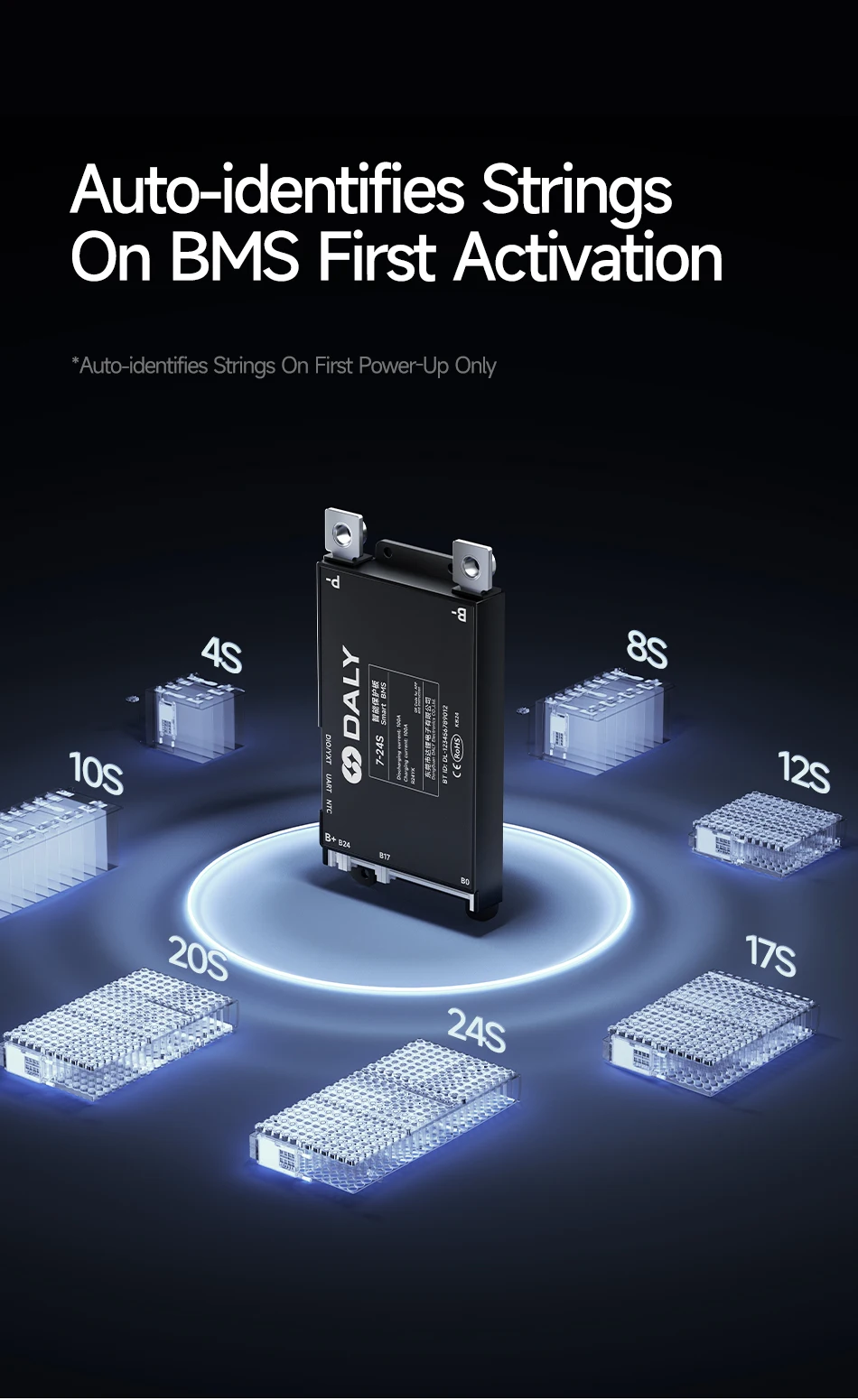

Optional strings range:4-8S 7-17S 7-24S |

|||||||||||

|

Optional current range:30A 40A 60A 80A 100A 120A |

|||||||||||

|

|

|||||||||||

|

|

|||||||||||

|

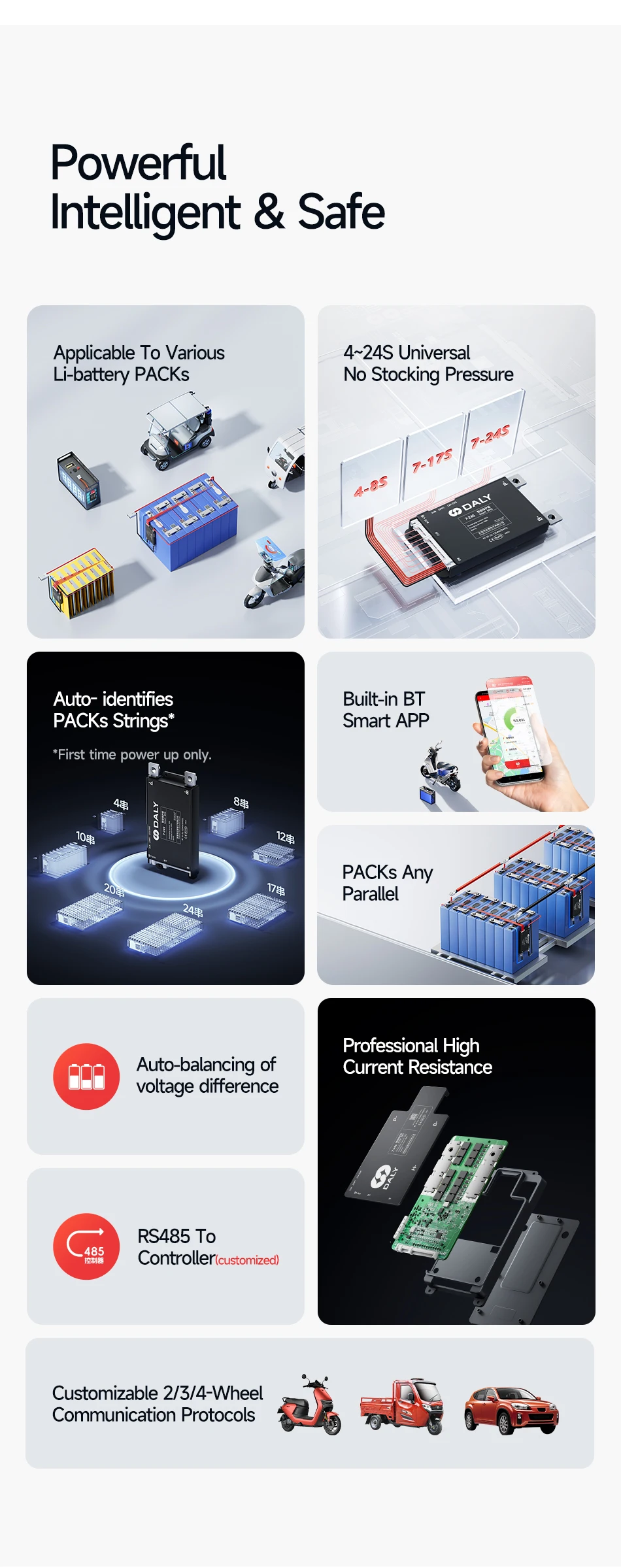

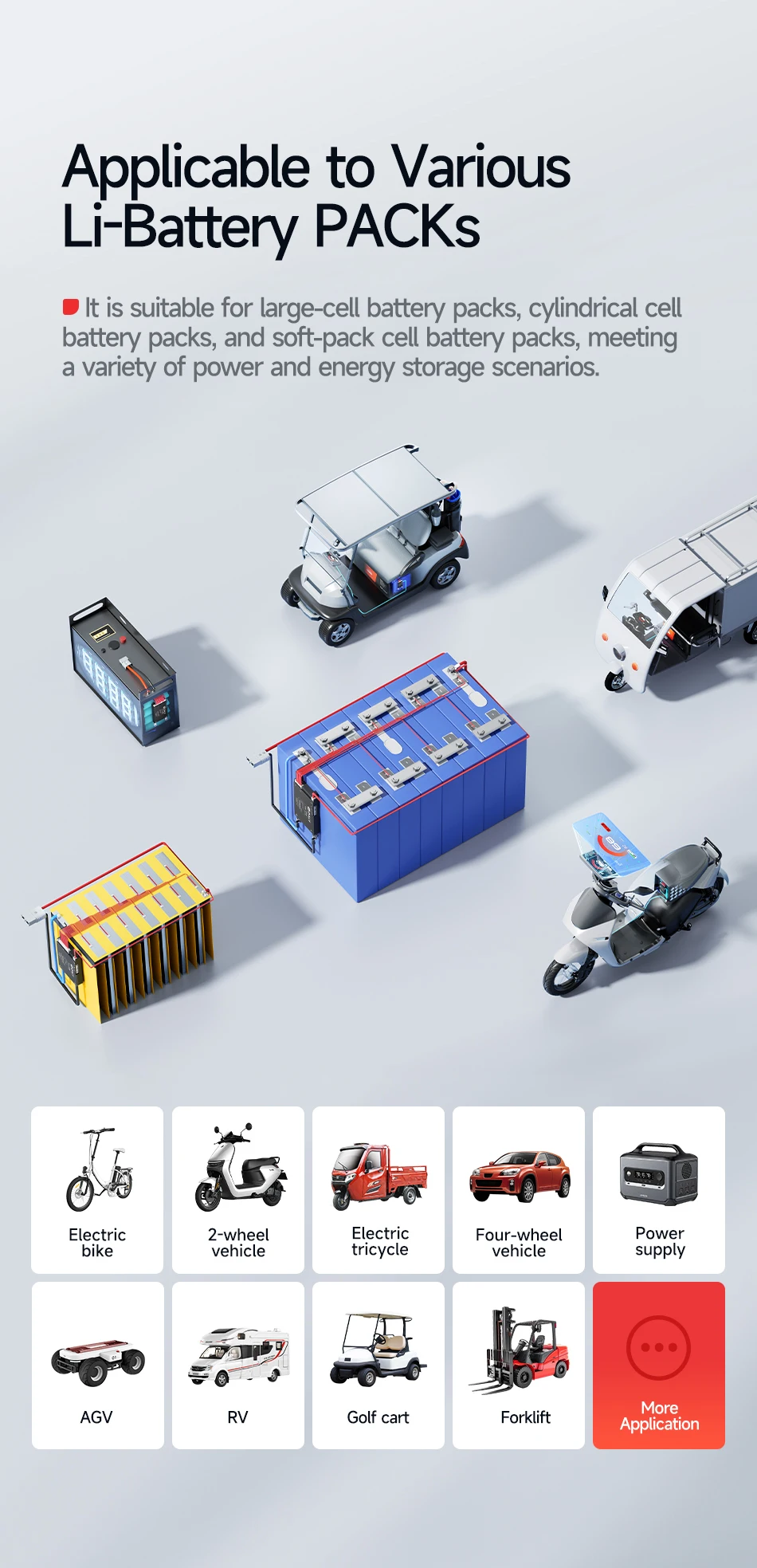

Usage Scenario |

|||||||||||

|

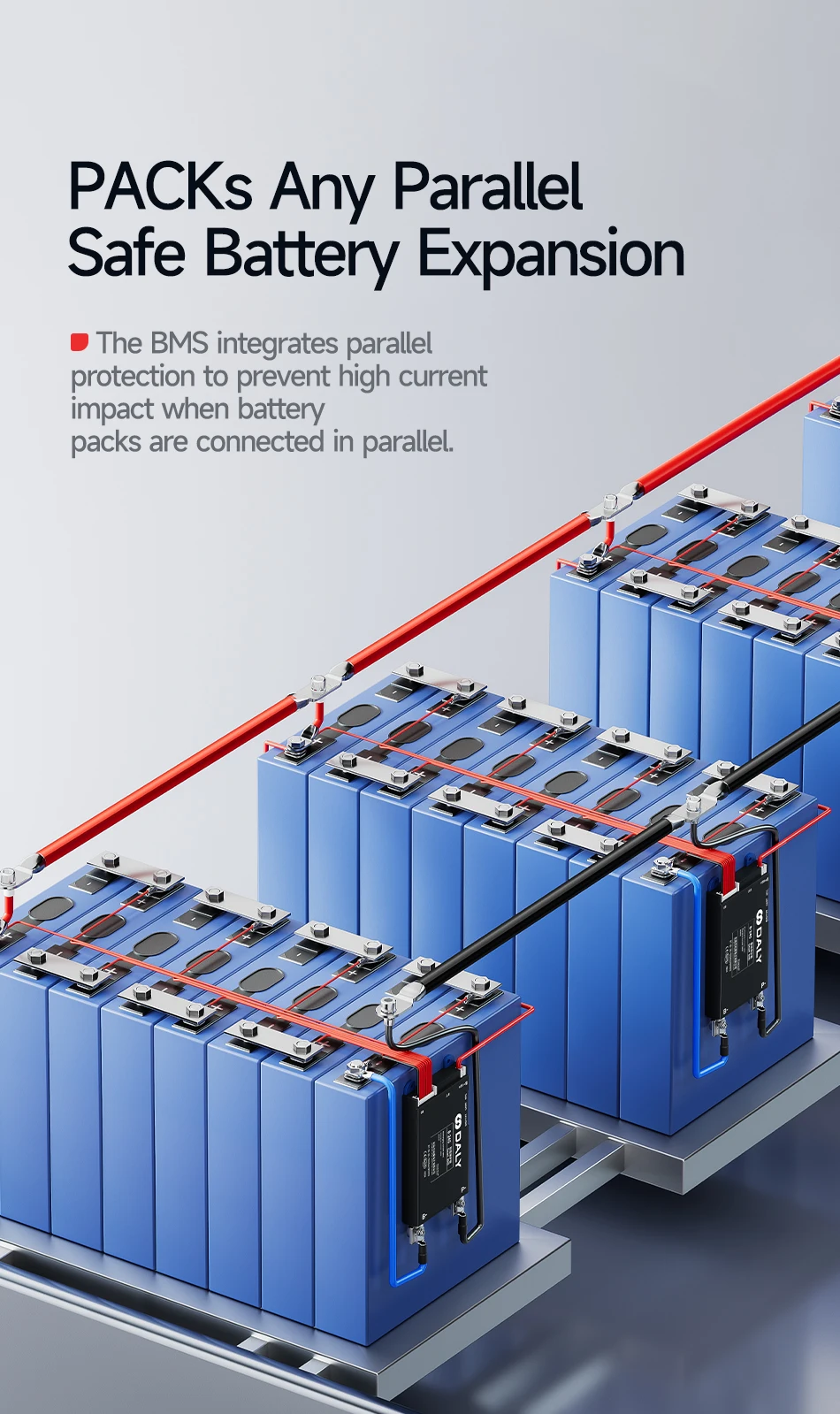

Used in RV energy storage,photovoltaic energy storage,home and outdoor energy storage,electric vehicles,tricycles,forklifts,tourist vehicles,golf cart etc. |

|||||||||||

|

|

|||||||||||

|

|

|||||||||||

|

Support Customization |

|||||||||||

|

Bulk orders can customize functions,parameters,logo. |

|||||||||||

|

Support OEM |

|||||||||||

|

Standard BMS, smart BMS all can be customized |

|||||||||||

|

For details, please contact customer service |

|||||||||||

|

|

|||||||||||

|

How to choose the right BMS |

|||||||||||

|

Attention |

Illustration |

Mismatched BMS Consequences |

|||||||||

|

Lithium |

BMS type and lithium battery type must be in |

1、BMS damaged,even bms and battery burn out |

|||||||||

|

battery type |

one-to-one correspondence(Li-ion/Lifepo4) |

2、The battery cannot be fully charged and discharged |

|||||||||

|

|

|

|

|||||||||

|

Number of battery pack |

BMS strings and battery strings must be in |

BMS and battery burn out |

|||||||||

|

strings |

one-to-one correspondence |

||||||||||

|

|

|

||||||||||

|

Selection method |

load maximum power÷(string number of battery×overdischarge voltage)×coefficient |

||||||||||

|

in experience |

Depending on the battery usage scenario, the coefficient value is also different |

||||||||||

|

|

Please consult customer service for specific values |

||||||||||

|

|

|||||||||||

|

Specialty |

|||||||||||

|

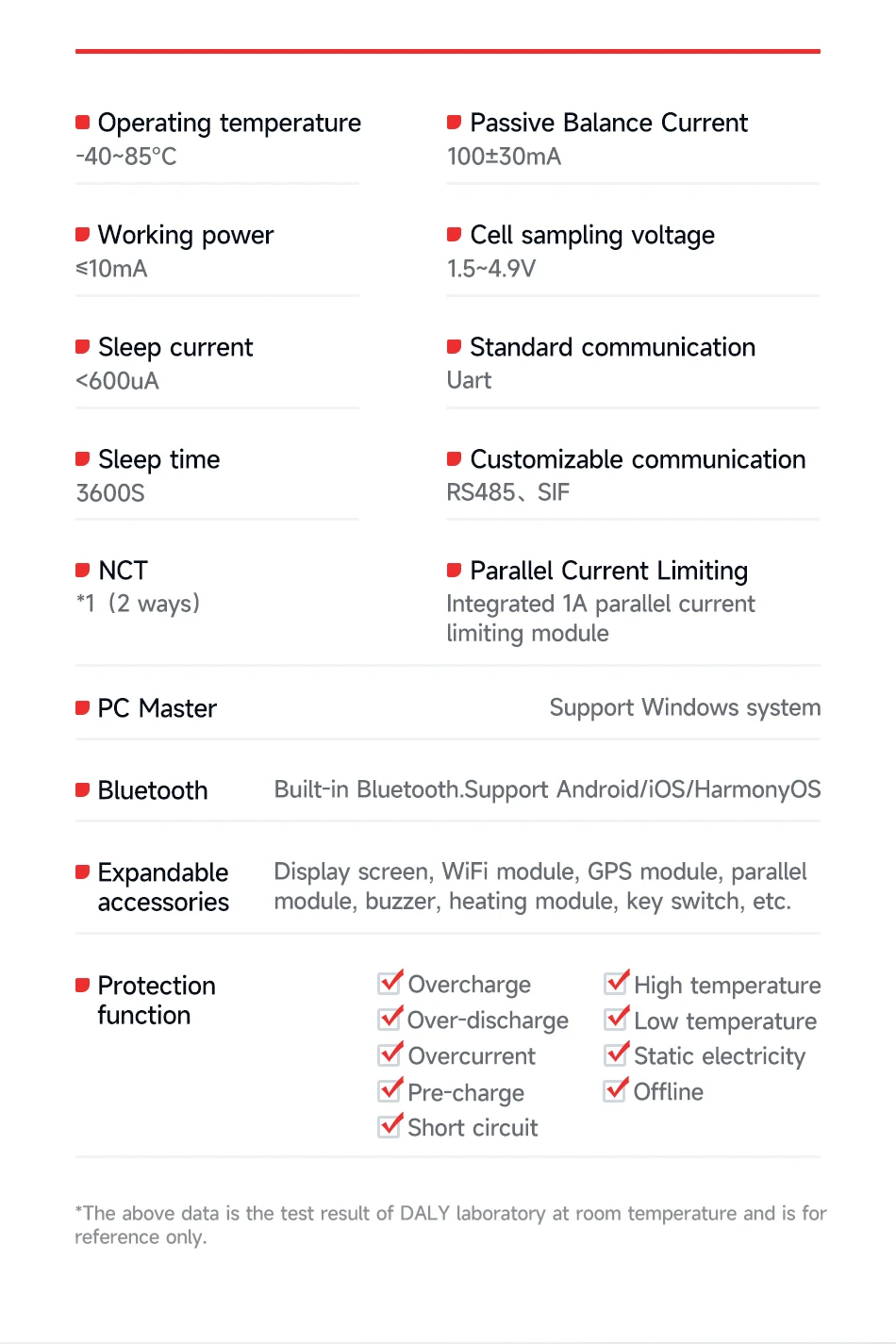

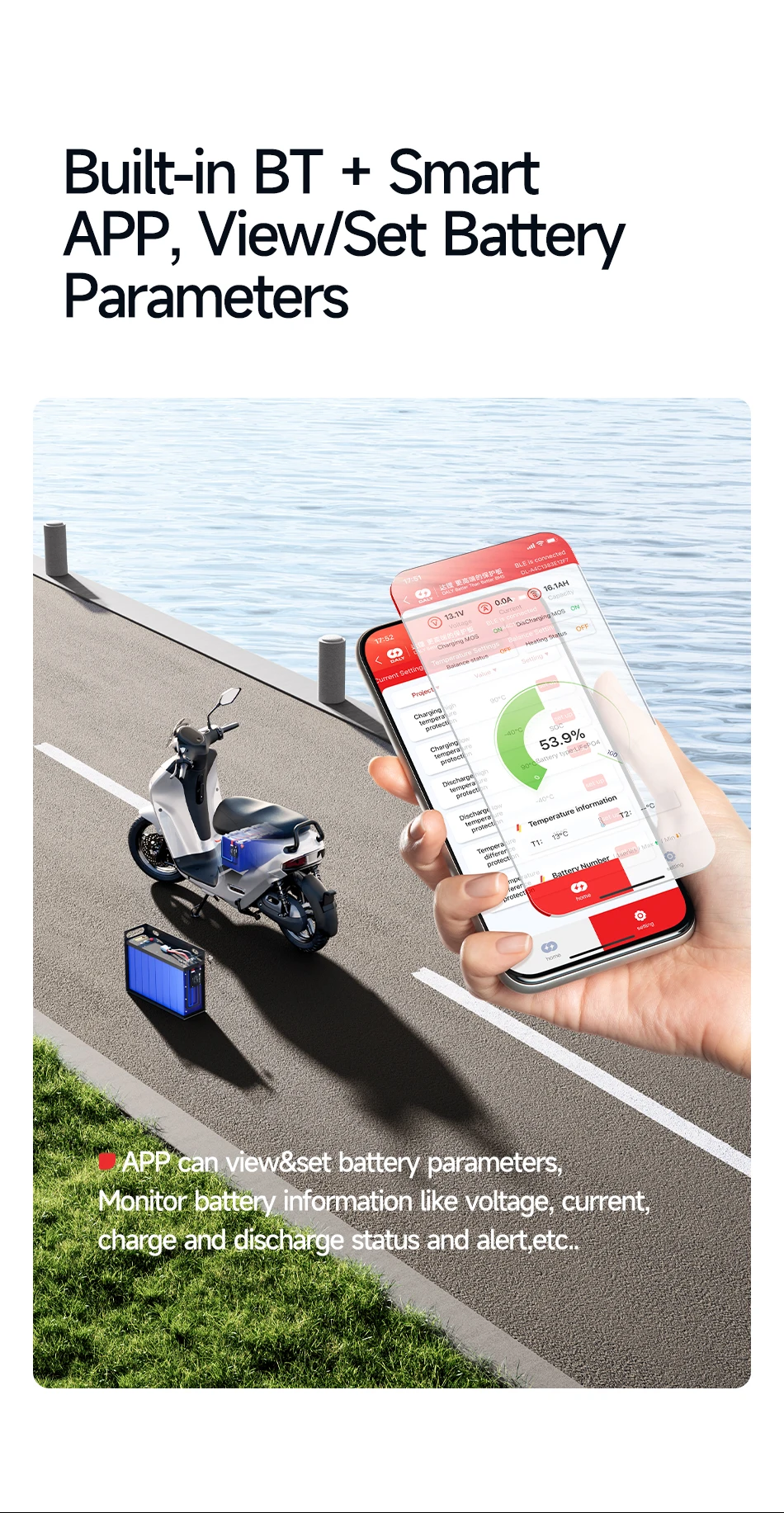

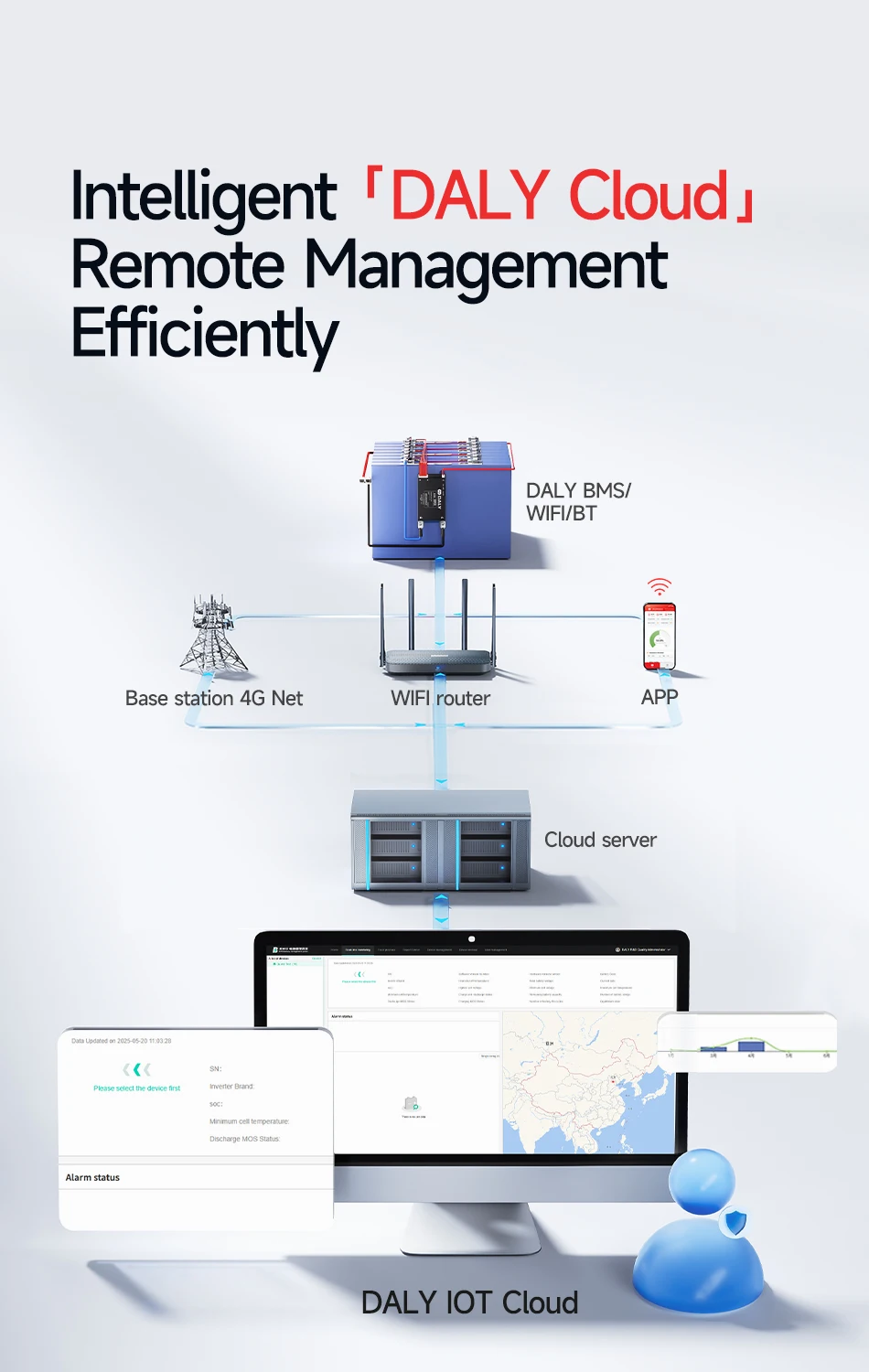

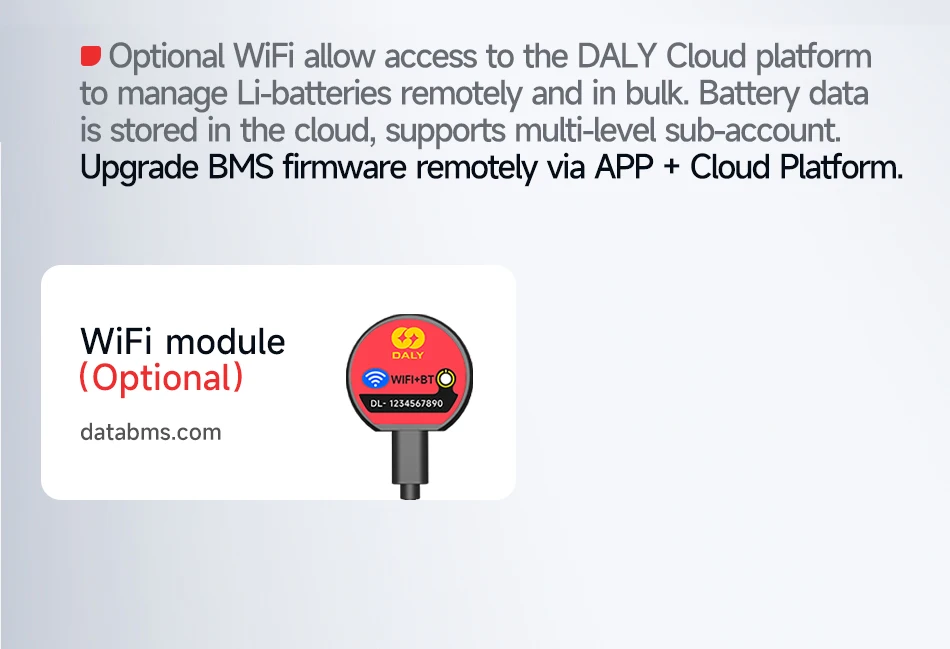

Bluetooth function:You can monitor battery data in real time by connecting to the APP |

|||||||||||

|

|

|||||||||||

|

Superiority |

|||||||||||

|

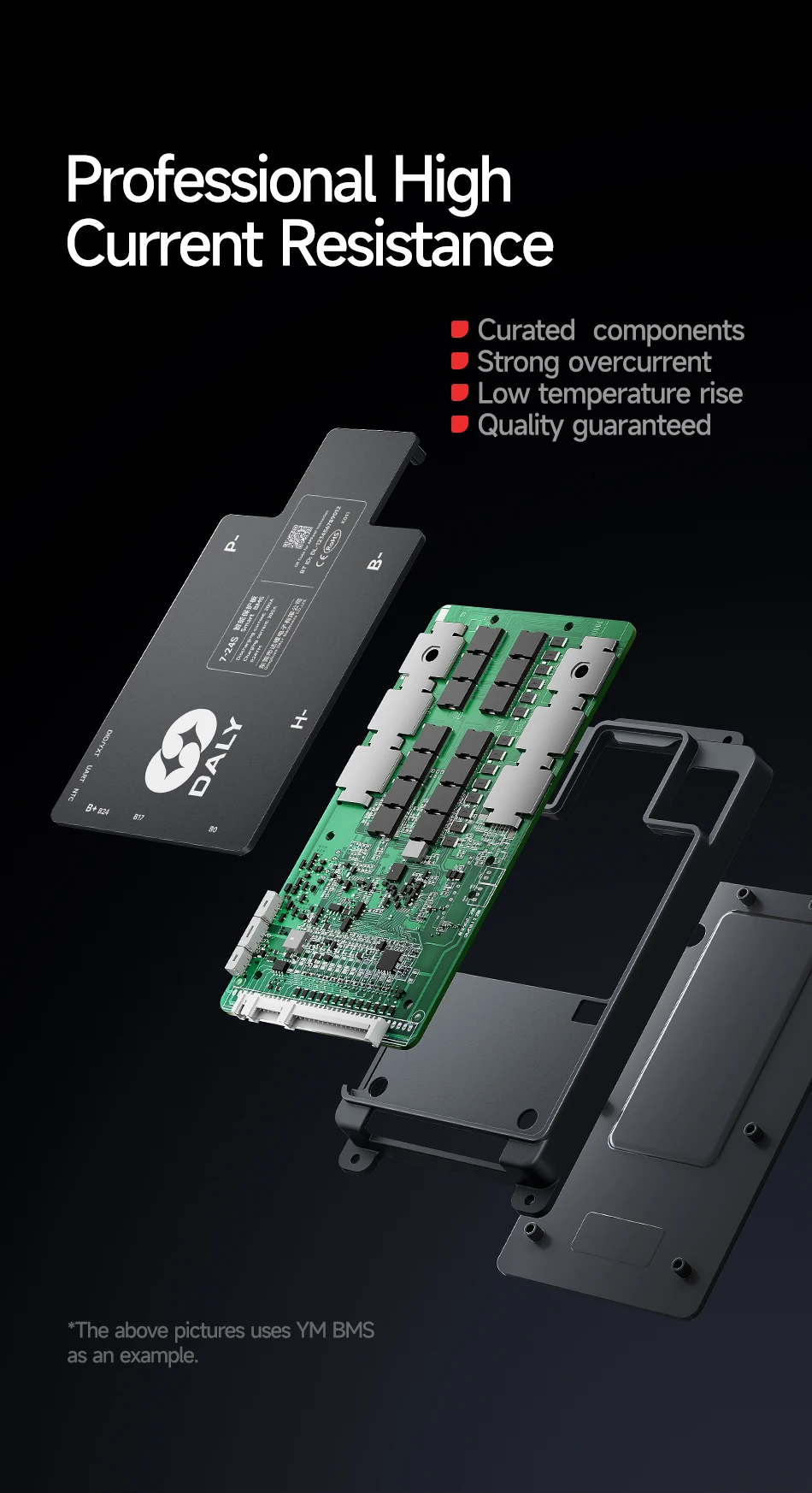

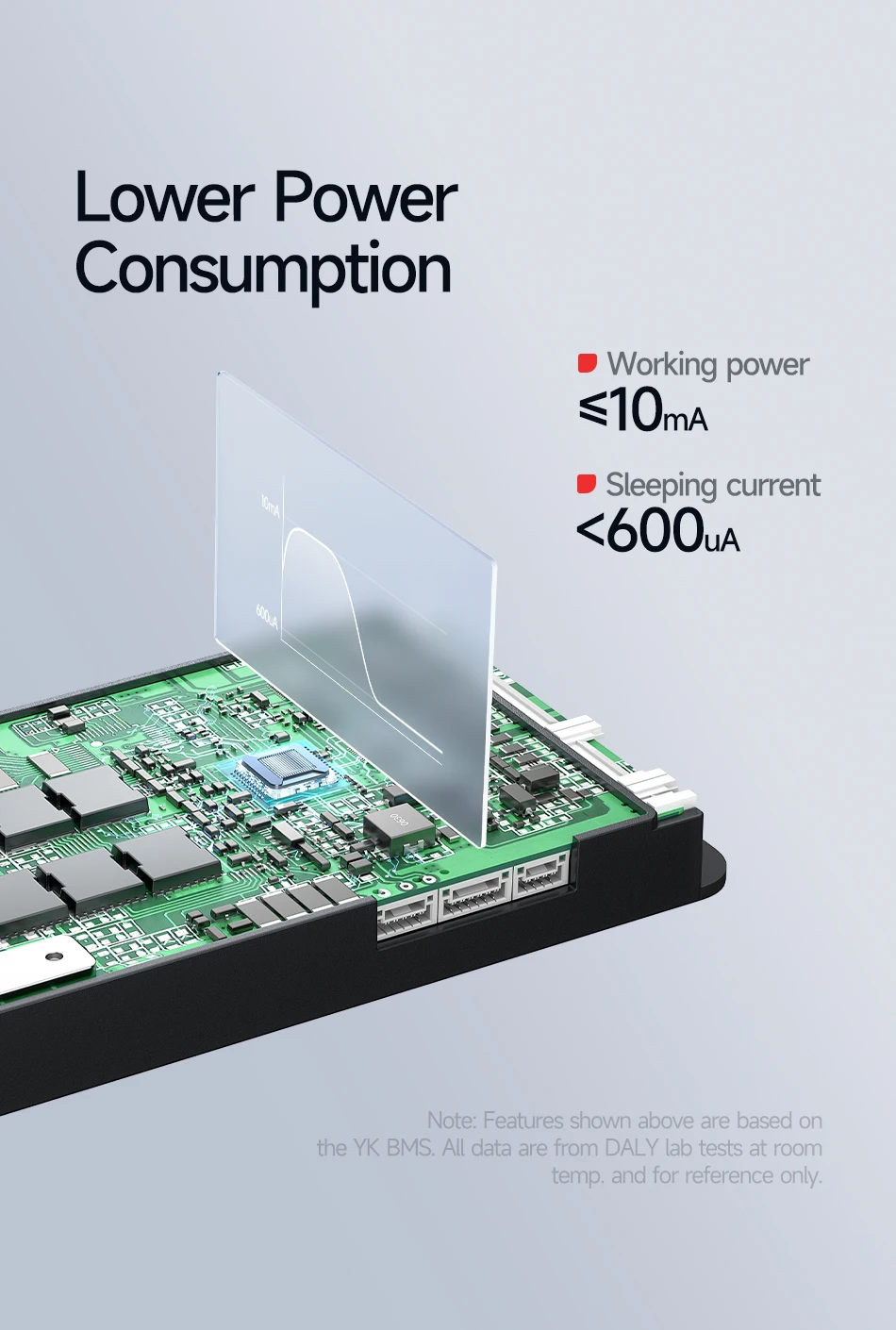

1、High-quality microelectronic components:precise and fast IC.Low resistance,high withstand voltage MOSFET. |

|||||||||||

|

2、Through the Bluetooth APP, the battery data is constantly monitored. |

|||||||||||

|

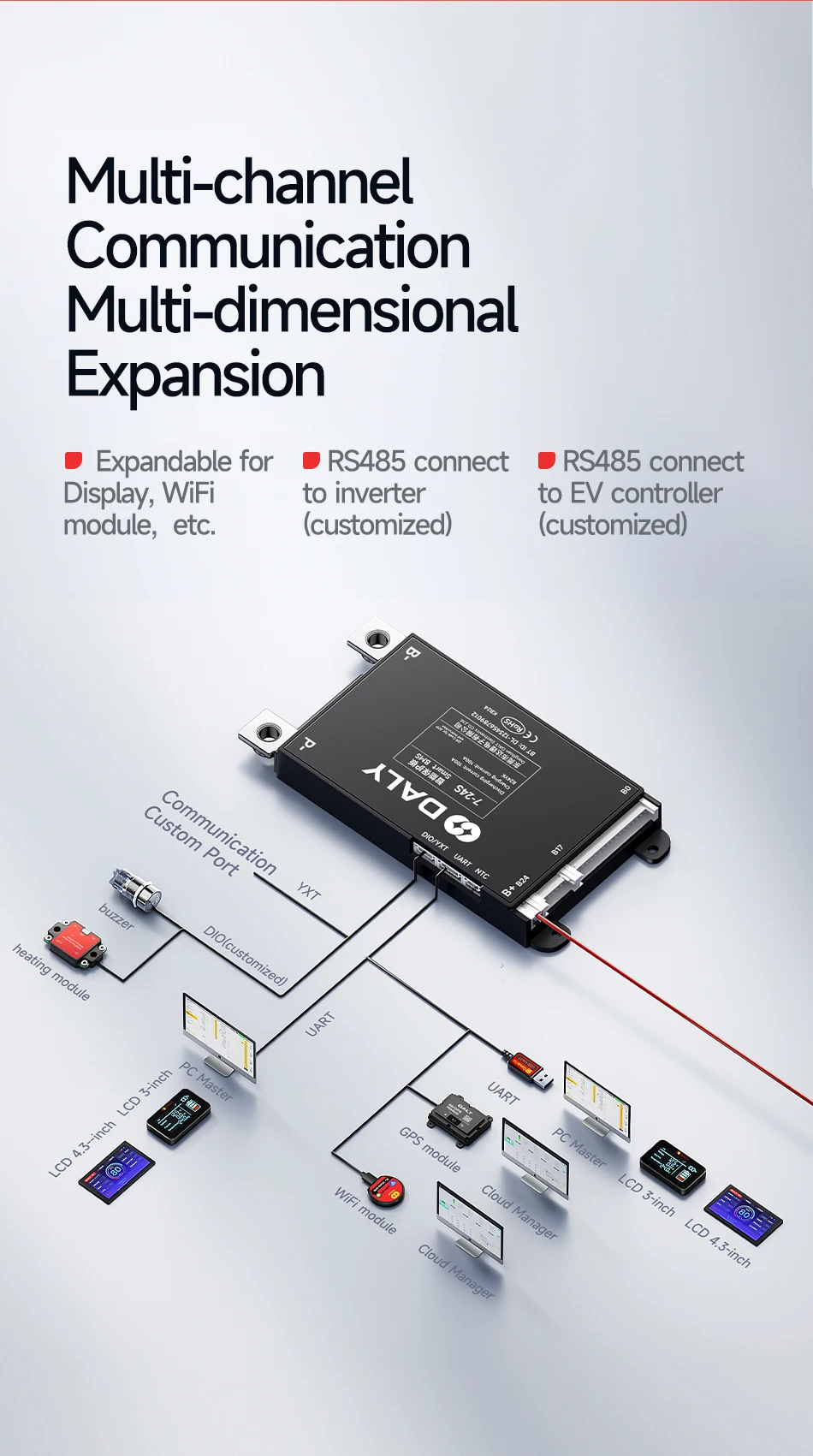

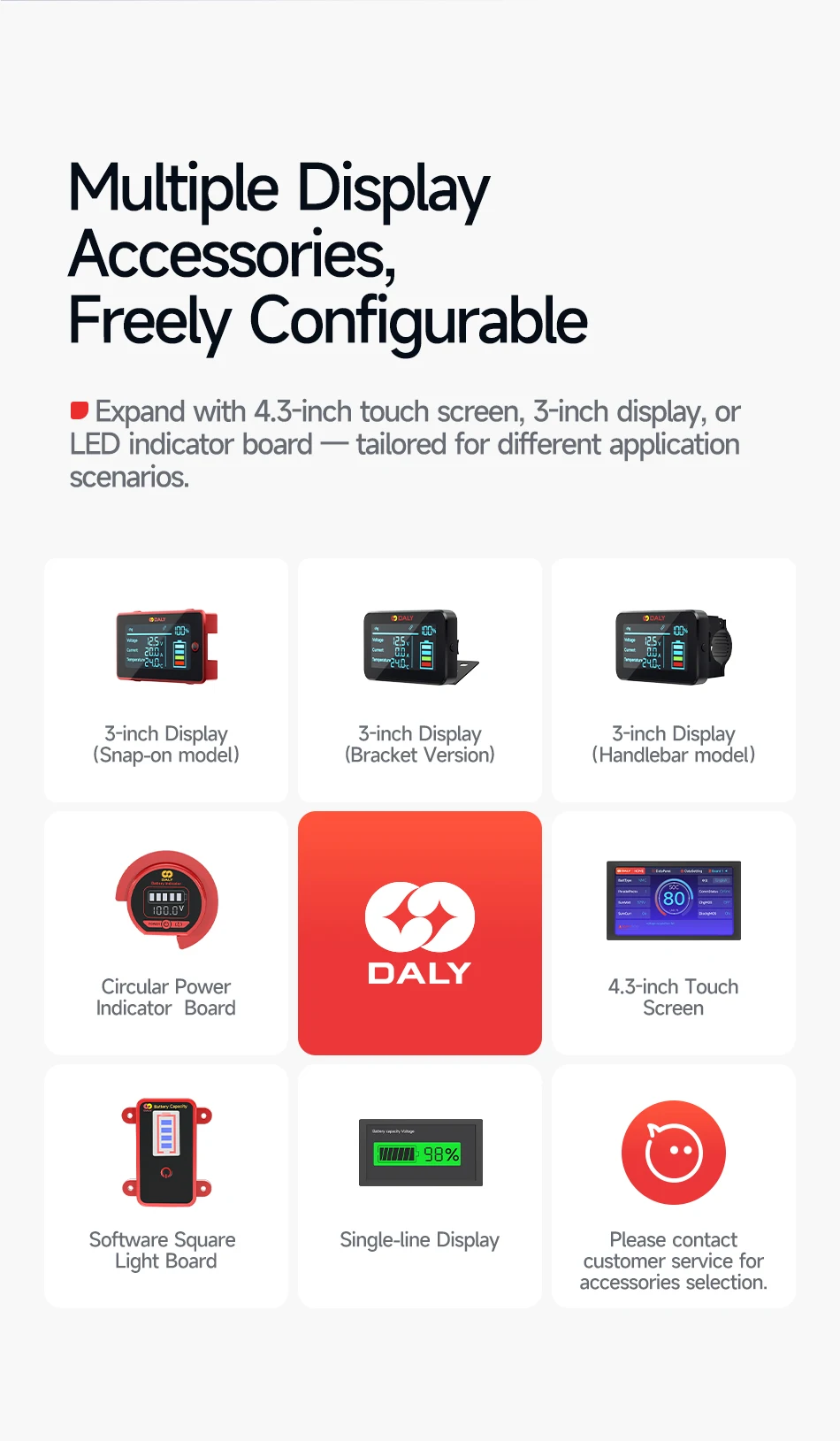

3、A variety of accessories,can easily control the data and modify the parameters. |

|||||||||||

|

4、A variety of communication modes,data monitoring,alarm backtracking,data reading, and upgrade can be easily realized |

|||||||||||

|

5、Thermal silica,accelerate the heat dissipation.Ensure the smooth operation of the battery. |

|||||||||||

|

6、Preset interface,buckle cable,make the connection more convenient. |

|||||||||||

|

|

|||||||||||

|

Basic Functions |

|||||||||||

|

Over-charging protection |

Over-discharging protection |

||||||||||

|

Over-current protection |

Temperature protection |

||||||||||

|

Disconnect protection |

Short Circuit Protection |

||||||||||

|

Balance Function |

Short Circuit protection recover |

||||||||||

|

|

|||||||||||

|

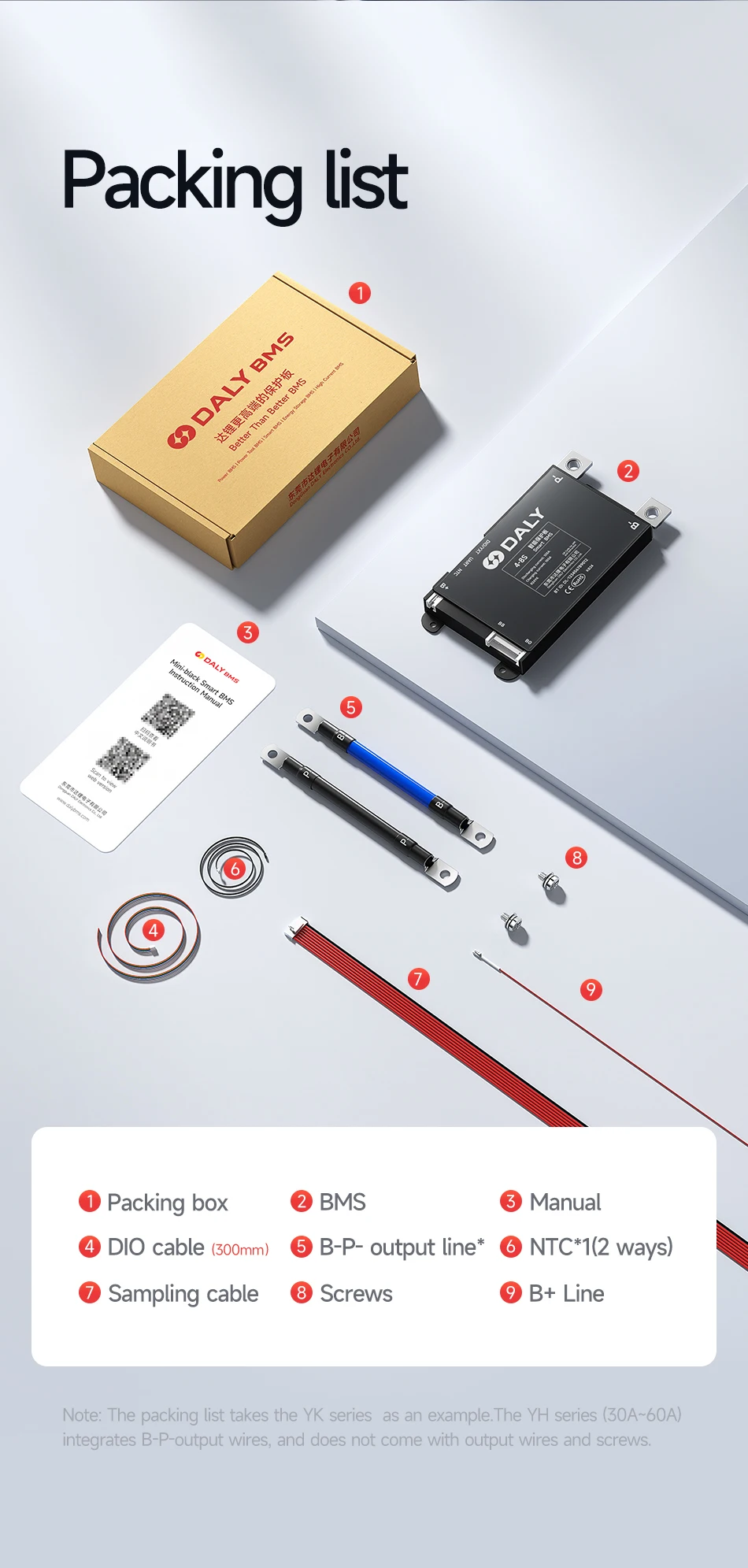

Package Contains |

|||||||||||

|

BMS*1pcs |

Sampling cable*1pcs |

Temperature probe(NTC)*1pcs |

|||||||||

|

B+ cable *1pcs |

English manual *1pcs |

USB-Uart cable *1pcs |

|||||||||

|

|

|||||||||||

|

Optional accessories |

|||||||||||

|

UART to USB cable |

Battery Capacity Indicator |

Touch screen LCD |

|||||||||

|

|

|||||||||||

|

Customization |

|||||||||||

|

soft switch |

RS485 and CAN Communication |

||||||||||

|

key switch |

DO/I port for special needs |

||||||||||

|

Optional accessories, customized accessories must match the BMS model and be purchased at the same time. |

|||||||||||

|

please contact customer service for details |

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

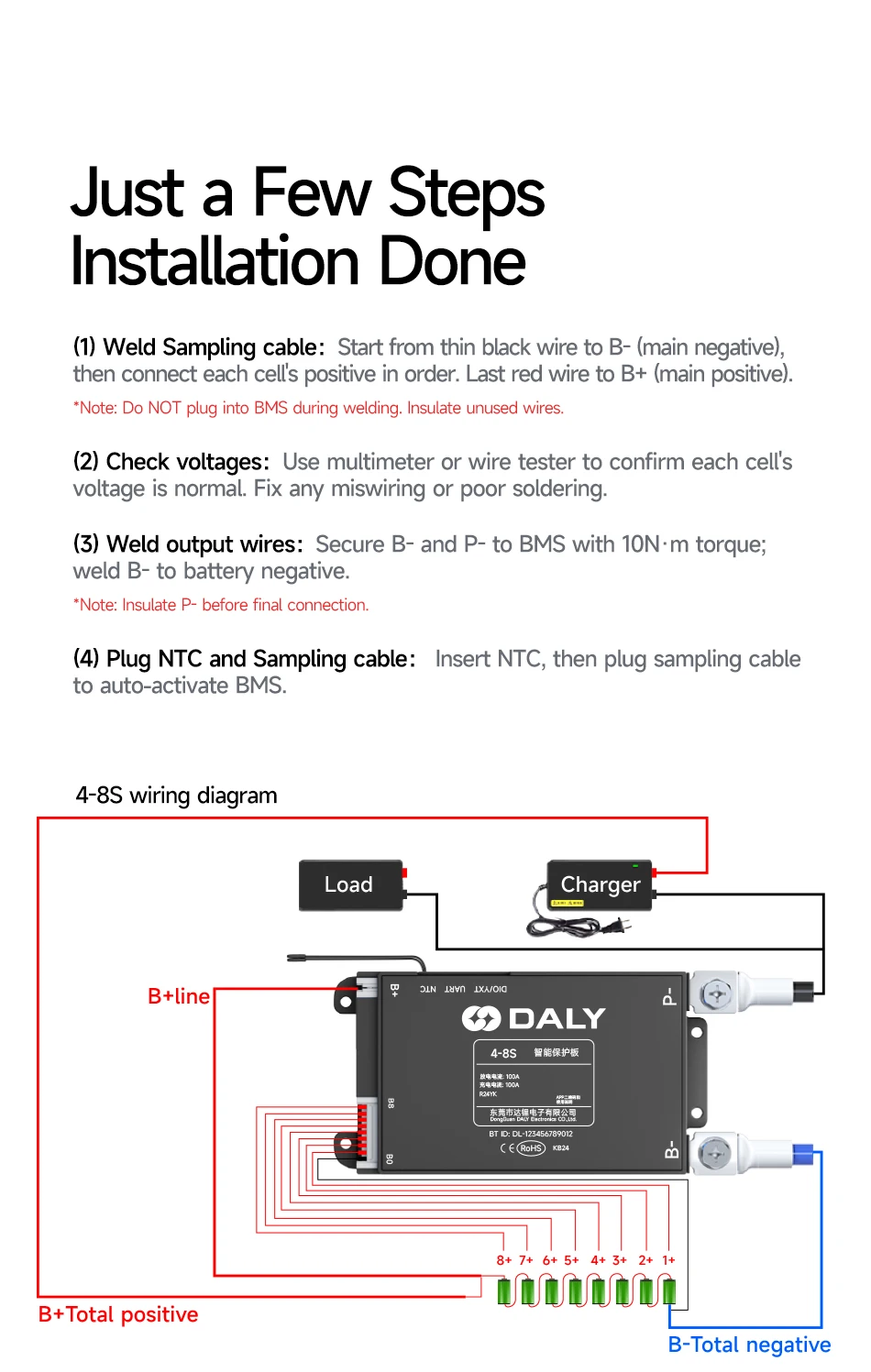

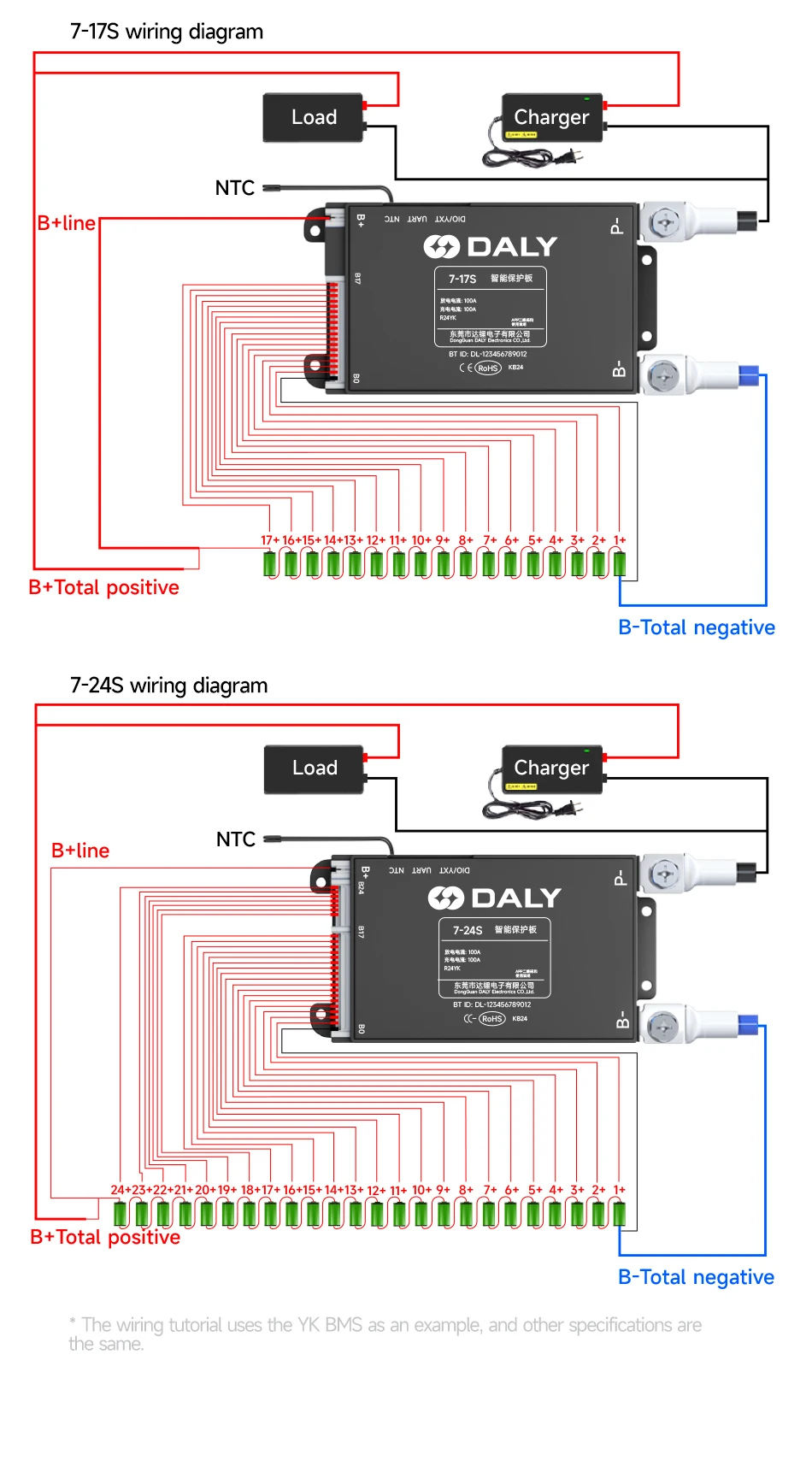

Balance cable connection |

|||||||||||

|

Find the total positive and total negative of the battery pack. |

||||||||||

|

Find B-/P- of BMS |

|||||||||||

|

Insert temperature probe (NTC) into the BMS |

|||||||||||

|

Note: When soldering, the balance cable cannot be inserted into the BMS |

||||||||||

|

(1)Weld Sampling cables: Start from thin black wire to B- (total negative),then connect each cell's positive in order. Last red wire to B+ (total positive) |

|||||||||||

|

(2)Check voltages: Use multimeter or wire tester to confirm each cell'svoltage is normal. Fix any miswiring or poor soldering. |

|||||||||||

|

(3) Weld output wires: Secure B- and P- to BMS with 10N·m torque; weld B-to battery negative. |

|||||||||||

|

(4) Plug NTC and Sampling cable: Insert NTC, then plug sampling cable toauto-activate BMS. |

|||||||||||

|

|

|||||||||||

|

Measure whether the battery voltage(B+→B-)is consistent with the output voltage of the BMS(B+ P-). |

||||||||||

|

If the two voltage values are equal, it means that the BMS is working normally. |

|||||||||||

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Passive Equalization |

|||||||||||

|

3.4V |

||||||||||

|

≥20mV |

||||||||||

|

100±30mV |

||||||||||

|

|||||||||||

|

1.Reach the set balanced start voltage |

|||||||||||

|

2.The highest voltage reaches the set balanced start voltage difference. |

|||||||||||